2019 Biesse Rover K FT 2231

Specifications

| Manufacturer | Biesse |

| Model | Rover K FT 2231 |

| Year | 2019 |

| Stock Number | MHG011 |

Description

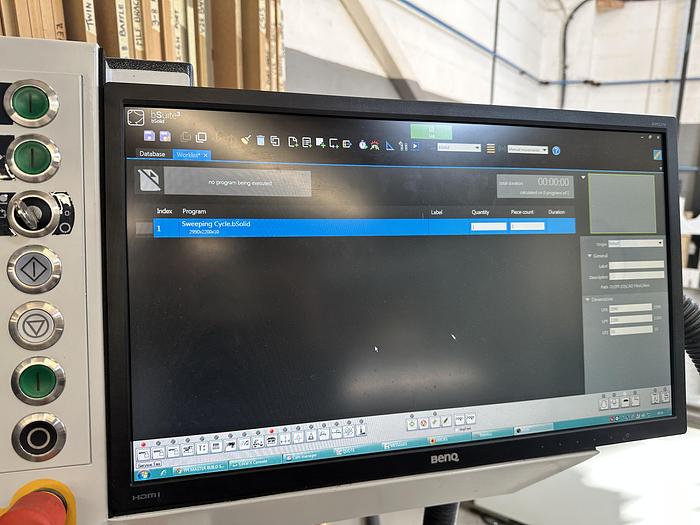

Numerical Control with B-Solid Software - 3D CAD-CAM program to design, simulate, and manage processes of machining of Biesse machining centers and drilling machines B Suite version 3.0.6.114 BNest Software - Software module dedicated to processing in Nesting mode that allows you to create projects containing the list of articles with the quantities to be produced and the list of plates to be used with the aim of minimize the material used and processing times Working field in X axis mm 3100 Working range in Y axis mm 2205 Nesting worktop in phenolic laminate with vacuum system with multi-zone technology that adapts automatically the vacuum of the machine to the different dimensions of the panels used by the customer inside the own production Predisposition for automatic unloading using the Sweeper arm system, it allows the unloading of pieces and the cleaning of the martyr panel, avoiding manual intervention and thus increasing productivity No. 1 liquid-cooled HSD 19.2 kW vertical electrospindle with HSK F63 automatic tool changer, 1,000-24,000 rpm. Suction hood adjustable in 6 positions Automatic tool measurement system Automatic tool change system with 14 positions - positioned on the machine side BH 17 boring head with spindles arranged as follows: * N° 10 verticals in X and Y axis * N° 6 horizontal in X and Y axis * Blade unit integrated in the boring head Safety system of new full bumper solution allows access to the worktop in total safety in every moment, on all sides Automatic lubrication system Air conditioning system for cooling and cleaning the machine control Rotary vacuum pump of 250 m3/h Automatic lubrication Optional: Front cover with opening instead of closed fixed cover (7022320) Installed power kW 28