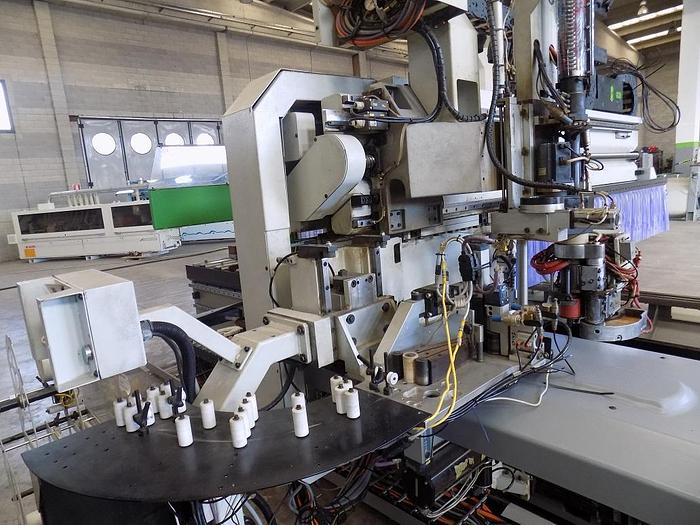

MEG016 BIESSE ROVER C 9.65 Edge Machining center with edging

Specifications

| Manufacturer | Biesse |

| Model | Rover C 9.65 Edge |

| Year | 2010 |

| Stock Number | MEG016 |

Description

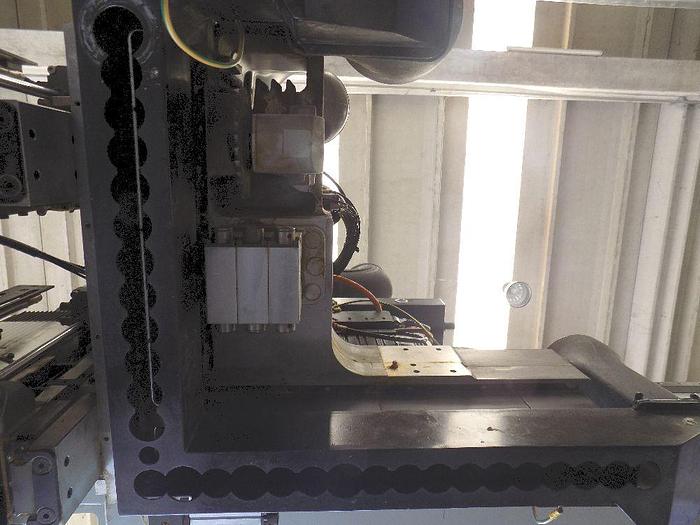

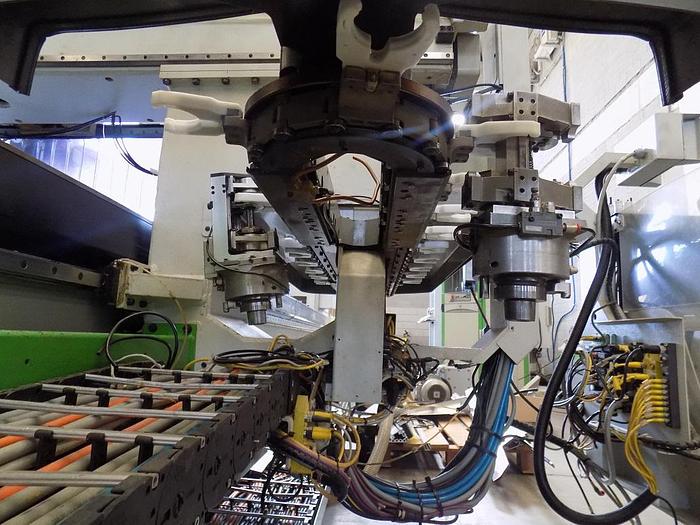

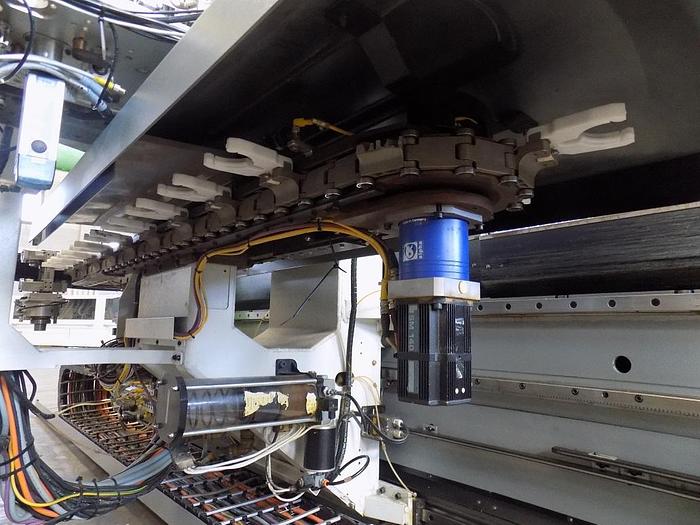

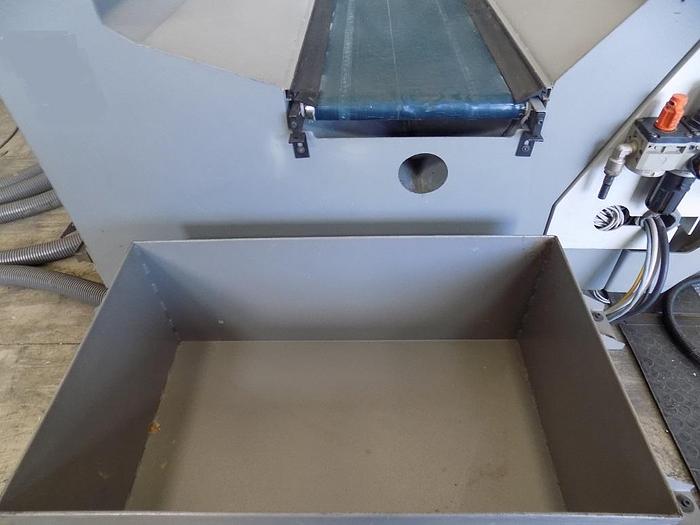

Working range in X - Y - Z: 6.200 - 1.935 - 225 mm Axis speed X-Y-Z: m / min. 100 - 100 - 30 'ATS' 10-bar worktop Trolleys per bar: nr. 4 Vacuum modules: nr. 40 Lateral (2 + 2) and bottom (2) reference stops Pendular machining up to 2,650 mm 2 independent working fields that allow the simultaneous processing of 2 identical, specular or different pieces they Easy positioning of heavy workpieces and large panels with the lifting device Machining of the five faces of the piece "Gooseneck" machine Milling unit: Nr. 2 HSD 4-axis electrospindles (C axis) - kw 12 Liquid cooling HSK F63 connection Rotation speed max rpm 24000 Inverter Edging Unit: Glue spreading on the panel Knurled roller to facilitate glue penetration on the panel surface Compact unit that allows you to edge concave profiles of reduced dimensions Independent granule feeding system to the gluing unit for loading in masked time. Thermoregulators digital for glue pot and glue spreading roller Compact and easily removable glue pot Roll holder magazine with 2 positions on the X carriage to reduce edge feeding times Edge cutting unit Edge supply axis managed by CN Edge heating lamps Edge thickness: 0.4 - 3 mm Workable panel thickness: 14 - 50 mm Trimming aggregate Edge scraper aggregate Tool magazine: Rear with chain with 24 positions Max tools diameter 250 mm Drilling unit: Vertical drilling spindles in X = 12, in Y = 17 Horizontal drilling spindles in X = 3 + 3, in Y = 2 + 2 Max rotation rpm 6.000 Integrated blade 120 mm Control system: XP 600 based on PC - Windows Operating System Software: BiesseWorks Ease of programming Importing files Control panel / remote console to manage the main functions in the preparation phases of the area work and tooling of the operating groups Teleservice and videodiagnosis: solution in real time Automatic guide lubrication Motorized belt for the removal of shavings and scraps 1 vacuum pump mc / h 250 Centralized suction pipe Safety devices: Side strips to protect the group Sensitive platforms Perimeter protections with access door Operating pressure: 6.5-7.5 bar Total installed power: 19 Kw Overall dimensions: mm. 9.616 x 5.370 x 2.800h Machine weight: 7.600 + 600 Machine documentation: Use and maintenance manual, software manual, spare parts catalog, wiring diagram, declaration of CE conformity.