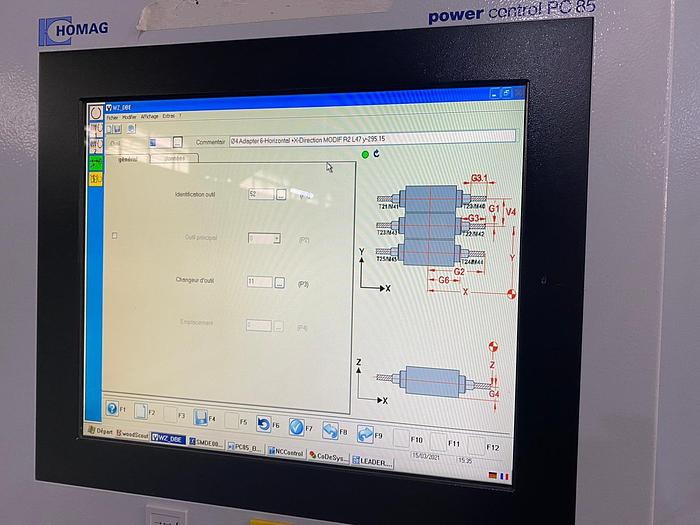

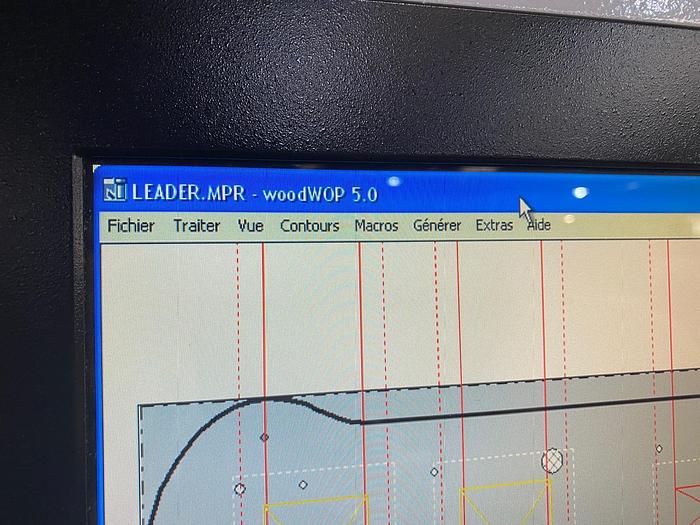

HOMAG PROFI BAZ 222/60 / K

Specifications

| Manufacturer | HOMAG |

| Model | Profi Baz 222/60/K |

| Stock Number | MGB016 |

Description

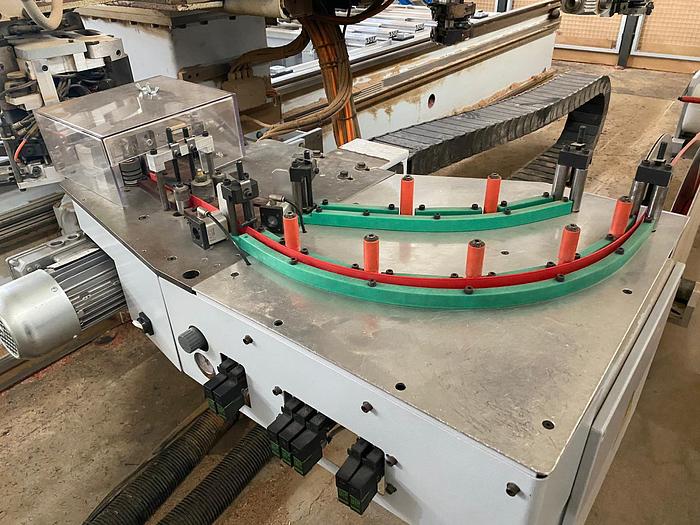

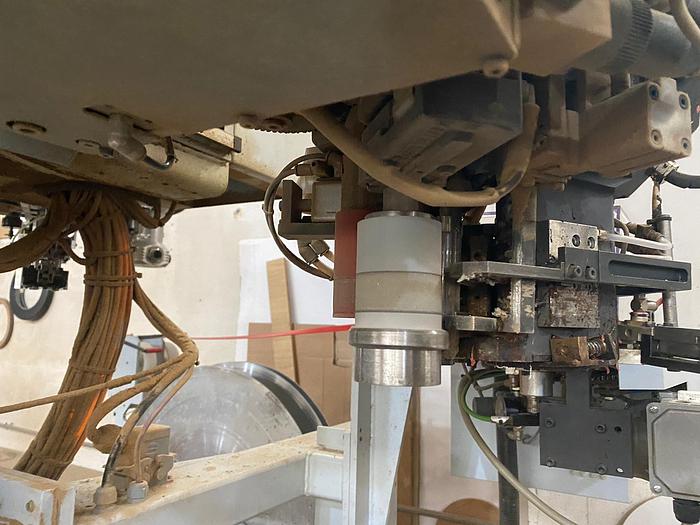

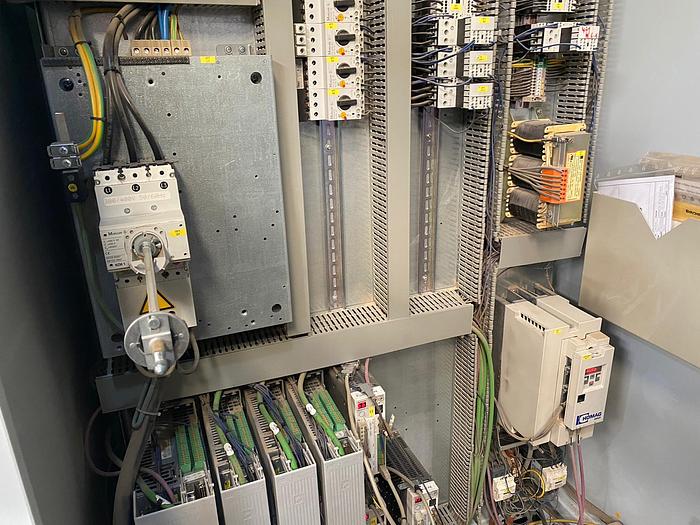

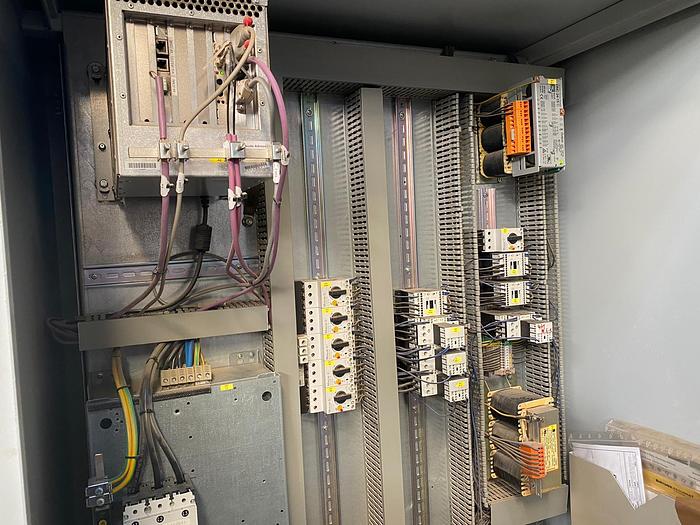

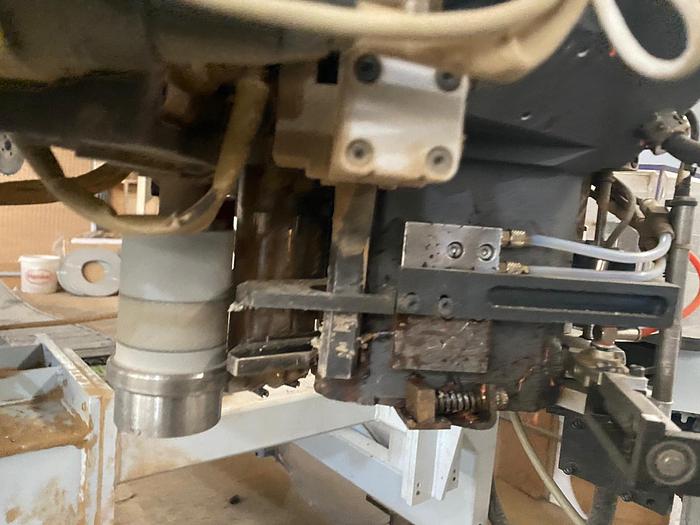

Numerical Control Power Control Homatic PC 85 with WoodWop 5.0 Software - Pack woodwop PC for working and programming from the BRAS BAZ office WOODSCOUT diagnostic system Working field in X axis 6000 mm Working range in Y axis 1650 mm (console B200) - in case of milling up to 1750 mm N ° 10 adjustable panel support bars for positioning the suction cups Loading and unloading aid system through 10 pneumatic bars positioned on each work bar N ° 3 Schmalz-type suction cups adjustable for each bar with vacuum seal for fixing the panel during the processing Positioning of the suction cups by means of a Laser system assembled on the main head N ° 1 vertical electrospindle with Vektor C axis with automatic tool change, cones type HSK F63, KW 11, with frequency converter Automatic tool change with 18 positions on the back of the machine Predisposition for FLEX -5 Boring head with 27 spindles (KW 4) arranged as follows: N ° 11 vertical in X axis N ° 6 vertical in Y axis N ° 6 horizontal in X N ° 1 horizontal cross head with 4 outputs for spindles and 0-90 ° adjustable blade from CN Independent edging unit with 360 ° rotation on the second Y axis with glue pot and pre-melter for granular EVA glue Applicable edges in rolls - PVC / ABS 0.4 - 3 mm Maximum working height in edging mm 60 Maximum applicable edge height mm 65 Internal radius min mm 30 (depending on the type of edge) External radius independent of the type of material used Rubberized pre-pressure roller + rubberized pressure roller Lamp for the pre-heating of the panel Edge cutter SYSTEME SERVICE for quick and simple disassembly and gluing unit N ° 1 blade aggregate, diameter 200 mm (max) N ° 1 combined trimming - edge scraper aggregate N ° 1 gleaning aggregate N ° 1 aggregate with cross of horizontal drilling with 4 outlets Edge holder magazine 2 positions Front protection and safety system with carpets Perimeter protection grids Chip evacuation system with motorized belt Air conditioning system for cooling and cleaning the machine control Automatic lubrication system N ° 2 reinforced vacuum pumps 100/140 m3 \ h each